What Are You Looking For?

What Are You Looking For?

Water-repellent Stylish Smiley Face Cow Suede Steel Toe Shoes For Women Indestructible Work Shoes Lightweight Puncture-proof Non-slip Safety Boots For Outdoors

MOQ :

1000prs/Color/StyleUpper :

Suede Leather/MeshLining :

FabricSole :

MD+RBColor :

GreySize Range :

36-41Season :

All SeasonsSample Time :

About 15daysLead Time :

60-75daysPayment :

T/T, LC at sightThese steel toe work boots are designed to provide durability, protection, and style. The upper is made from water-repellent cow suede leather, ensuring resistance against water and other liquids encountered in various work environments. This feature helps to keep the feet dry and comfortable throughout the day.

The boots are equipped with a steel toe cap, offering excellent protection against impacts and compression. This protective feature safeguards the toes from heavy objects or accidental drops, reducing the risk of injuries.

Adding a touch of style and breathability, these boots incorporate a unique smiley face mesh design. This mesh material not only enhances the boots' aesthetic appeal but also allows for proper air circulation, preventing excessive sweating and maintaining a comfortable environment for the feet.

To ensure safety and stability, the boots are constructed with a non-slip outsole. This outsole delivers exceptional grip and traction on various surfaces, reducing the chances of slipping or falling. It provides stability and confidence while maneuvering through slippery or uneven terrains.

Moreover, these boots are puncture-proof, providing an additional layer of protection. The sole is reinforced with materials designed to resist punctures from sharp objects, such as nails or shards of glass. This feature ensures that the wearer's feet are shielded from potential injuries caused by penetrating objects.

In summary, these steel toe work boots combine functionality, durability, and style. With their water-repellent cow suede leather upper, steel toe cap, smiley face mesh, non-slip outsole, and puncture-proof construction, they offer protection, comfort, and a touch of personality for individuals working in various industries.

Frequently Asked Questions

Are You a Factory or a Trading Company?

We are a factory that specializes in manufacturing premium waterproof shoes. Also,We have our own brand - @R CORD, and you can find our products on Amazon's platform.

Do you offer OEM/ODM services?

We can manufacture shoes according to our clients' specific requirements, as well as produce shoes under our own brand.

What is your minimum order quantity?

Typically our MOQ is 1000 Pairs/Color/Style.

Can you provide samples of your shoes?

We can typically have a sample ready within 3 days using our existing materials, sole molds, and lasts. However, if new materials are required, it may take up to 15 days to complete the sample. Please note that sample fees and shipping costs will be charged, but these charges will be refunded once a bulk order is placed.

What is your lead time for production?

Lead time depends on the order quantity, normally ranging from 60-75 days for an order of 10,000 pairs.If there is a delay, we will proactively keep you informed about the status and provide possible solutions in advance.

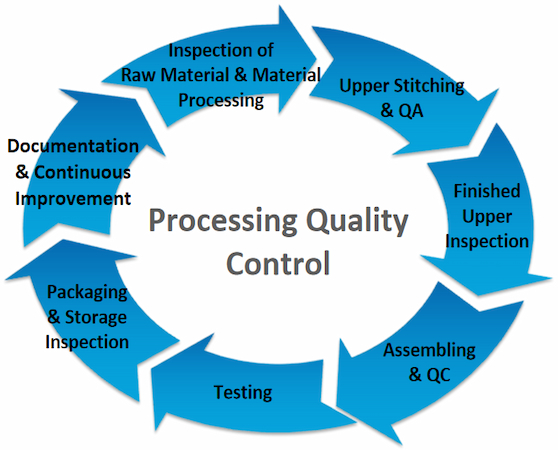

What is your quality control process?

Our professional QA/QC team oversees every aspect of the production process, from inspecting incoming materials to conducting in-process and finished product inspections, performing testing, managing corrections and rework, and overseeing packaging and shipping, to ensure that each order meets the highest quality standards.

Can you produce shoes according to our own design and specifications?

We can customize our shoes to meet each client's specific needs and preferences, including size, color, and design.

What payment methods do you accept?

We accept TT (30% deposit, 70% against copy of BL) or LC at sight.

Quality Control Process

1.Incoming Raw Material Inspection: Checking the materials for any defects, such as color variation, texture, and thickness.

2.In-Process Inspection: The quality control team Inspects cutting, stitching, lasting, and finishing processes. The team also checks for any defects such as uneven stitching, glue stains, and damage to the material.

3. Pre-Final Inspection: Checking for scratches, stains, and unevenness.

4. Final Inspection: The QC team checks each pair of shoes for any defects, such as stitching issues, incorrect sizing, and damage. The team also checks the shoes' overall appearance, including color, texture, and finishing.

5.Packaging Inspection: The team checks the packaging for any defects, such as incorrect labeling, incorrect packaging materials, and damage.

6. Testing: Conducting tests to ensure that the shoes meet the required performance standards. The tests may include abrasion resistance, flex resistance, water resistance and compression.

7. Documentation & Continuous Improvement: Recording all inspections, tests, and corrective actions taken. The QC team analyzes the documentation and identifies areas for improvement.

Factory Pictures

Why Choose Us?

Experience

Experience

Quality

Quality

Customization

Customization

Sustainability

Sustainability

Markets

Markets

Team

Team

Tags :