What Are You Looking For?

What Are You Looking For?

Men's Waterproof Split Leather Military Tactical Work Boots With Side YKK Zipper Lightweight Durable Hiking Motorcycle Combat Boots For Outdoors

MOQ :

1000prs/Color/StyleUpper :

Split Leather/MeshLining :

FabricSole :

MD+RBColor :

BlackSize Range :

41-46Season :

All SeasonsSample Time :

About 15daysLead Time :

60-75daysPayment :

T/T, LC at sightThese military tactical boots are designed to meet the demands of rigorous outdoor activities and combat situations. They are constructed with a focus on durability, functionality, and comfort. Here are their notable features:

Waterproof Construction: These boots feature a waterproof construction that keeps your feet dry even in wet and challenging environments. The materials used and the design ensure that water doesn't penetrate the boots, providing protection and comfort during missions or outdoor adventures.

High-Quality Split Leather Upper: The upper part of these boots is made from high-quality split leather. This type of leather is known for its strength, flexibility, and resistance to wear and tear. It provides excellent protection against abrasions and ensures the boots can withstand tough conditions.

Non-Slip Outsole: The outsole of these tactical boots is specifically designed to provide superior traction and grip on various surfaces. It features a non-slip pattern that offers stability and prevents slips and falls, even in slippery or uneven terrains.

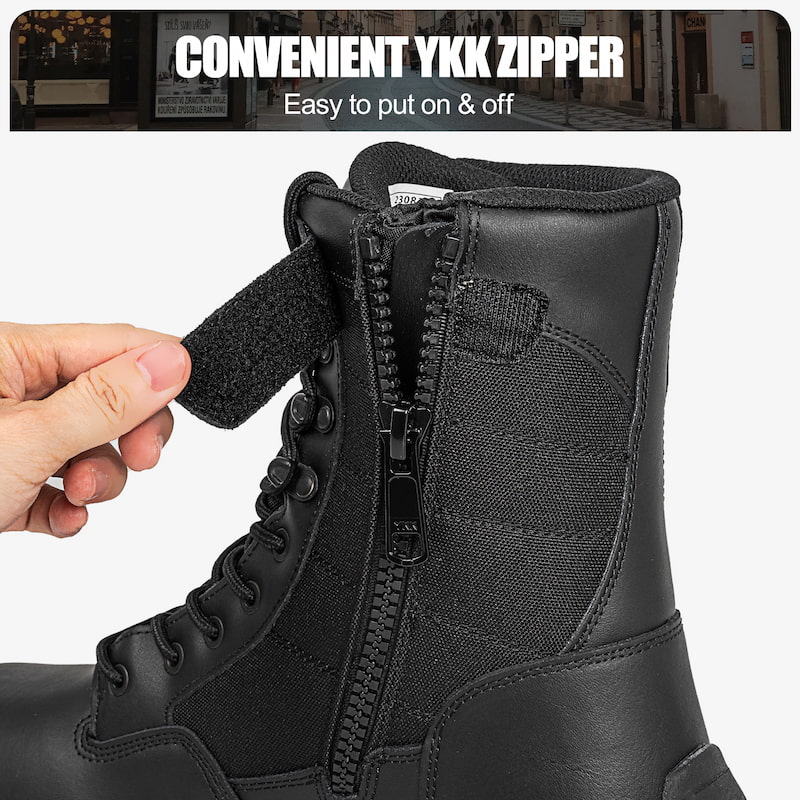

YKK Side Zipper: The inclusion of a YKK side zipper allows for easy on and off. This zipper is known for its reliability and smooth operation. It enables quick and convenient access to the boots, saving time and effort during rapid deployment or when taking them off after a long day.

Abrasion Resistant: These boots are built to withstand abrasions and resist damage from rugged terrains, jagged rocks, or other potential hazards encountered during military operations or outdoor activities. The materials and reinforced stitching enhance their durability and longevity.

Lightweight and Comfortable: Despite their rugged construction, these tactical boots are designed to be lightweight and comfortable. They incorporate features like cushioned insoles and breathable linings to provide comfort during extended wear. The boots offer the necessary support and stability without compromising on mobility and agility.

Frequently Asked Questions

Are You a Factory or a Trading Company?

We are a factory that specializes in manufacturing premium waterproof shoes. Also,We have our own brand - @R CORD, and you can find our products on Amazon's platform.

Do you offer OEM/ODM services?

We can manufacture shoes according to our clients' specific requirements, as well as produce shoes under our own brand.

What is your minimum order quantity?

Typically our MOQ is 1000 Pairs/Color/Style.

Can you provide samples of your shoes?

We can typically have a sample ready within 3 days using our existing materials, sole molds, and lasts. However, if new materials are required, it may take up to 15 days to complete the sample. Please note that sample fees and shipping costs will be charged, but these charges will be refunded once a bulk order is placed.

What is your lead time for production?

Lead time depends on the order quantity, normally ranging from 60-75 days for an order of 10,000 pairs.If there is a delay, we will proactively keep you informed about the status and provide possible solutions in advance.

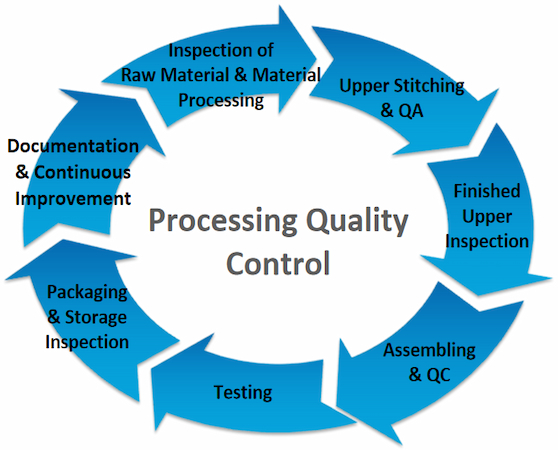

What is your quality control process?

Our professional QA/QC team oversees every aspect of the production process, from inspecting incoming materials to conducting in-process and finished product inspections, performing testing, managing corrections and rework, and overseeing packaging and shipping, to ensure that each order meets the highest quality standards.

Can you produce shoes according to our own design and specifications?

We can customize our shoes to meet each client's specific needs and preferences, including size, color, and design.

What payment methods do you accept?

We accept TT (30% deposit, 70% against copy of BL) or LC at sight.

Quality Control Process

1.Incoming Raw Material Inspection: Checking the materials for any defects, such as color variation, texture, and thickness.

2.In-Process Inspection: The quality control team Inspects cutting, stitching, lasting, and finishing processes. The team also checks for any defects such as uneven stitching, glue stains, and damage to the material.

3. Pre-Final Inspection: Checking for scratches, stains, and unevenness.

4. Final Inspection: The QC team checks each pair of shoes for any defects, such as stitching issues, incorrect sizing, and damage. The team also checks the shoes' overall appearance, including color, texture, and finishing.

5.Packaging Inspection: The team checks the packaging for any defects, such as incorrect labeling, incorrect packaging materials, and damage.

6. Testing: Conducting tests to ensure that the shoes meet the required performance standards. The tests may include abrasion resistance, flex resistance, water resistance and compression.

7. Documentation & Continuous Improvement: Recording all inspections, tests, and corrective actions taken. The QC team analyzes the documentation and identifies areas for improvement.

Factory Pictures

Why Choose Us?

Experience

Experience

Quality

Quality

Customization

Customization

Sustainability

Sustainability

Markets

Markets

Team

Team

Tags :